How Watch Cases Are Made: From Raw Metal to Finished Timepiece

A watch case is not born shiny or elegant, it is shaped, refined and obsessively finished until it becomes the silent bodyguard of a mechanical heart

Watch cases do not begin life looking like the sort of thing you would proudly place on your wrist while explaining to strangers why mechanical watches still matter. They start off as sheets or blocks of metal that look about as exciting as kitchen worktops. Steel titanium gold sometimes even exotic alloys. And yet somewhere in Switzerland often in places so quiet you can hear your own thoughts echo these lumps are about to be transformed into something precise beautiful and slightly obsessive.

At timepiece maker TAG Heuer, this transformation happens in dedicated case making facilities where control is everything. Not outsourced not guessed not rushed. Every case begins with metal that has already passed strict quality checks because there is no point building a Formula One car out of soggy cardboard.

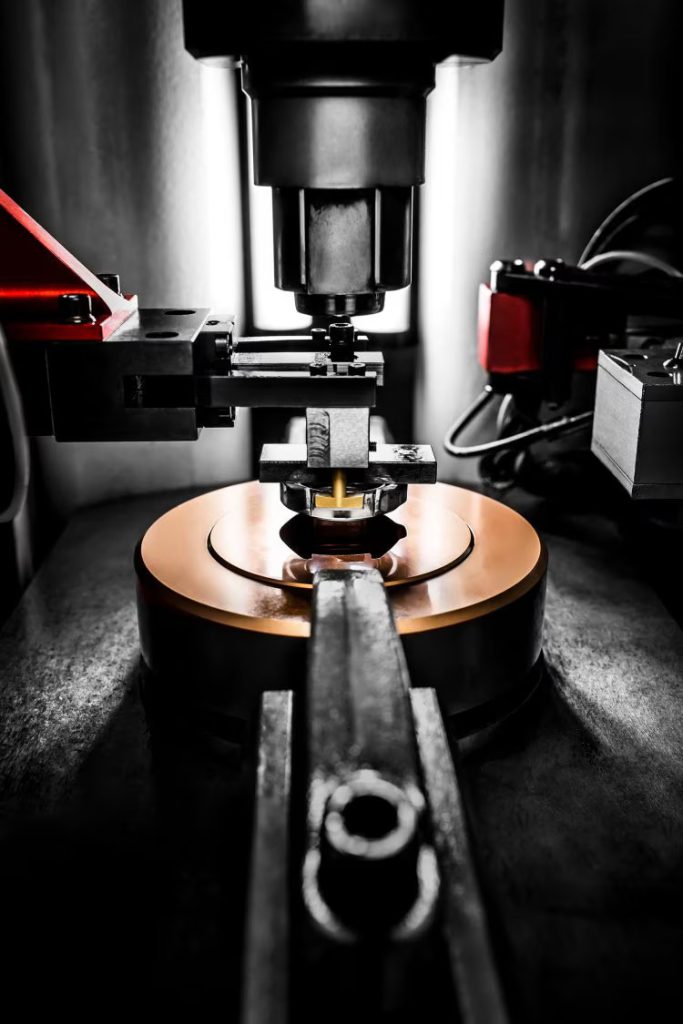

Stamping

The first proper step is stamping and this is where things get loud. Massive presses come down with terrifying force to punch out the basic shape of the case. It is controlled violence really. The metal is squeezed and reshaped again and again with heating and cooling cycles in between to keep it strong but workable. This process creates a rough case blank which at this stage looks like a watch case that has had a very bad day. But it has potential and that is what matters.

Also Read: Opera Vantara Green Camo Watch: A Closer Look at This Exclusive Timepiece from Jacob & Co.

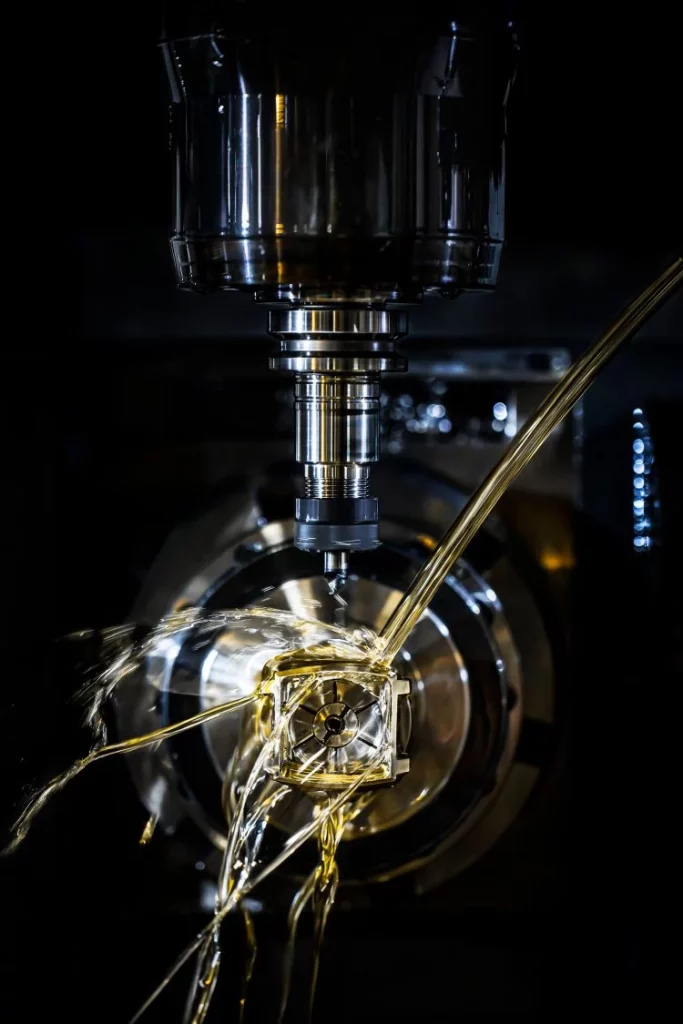

Machining

Next comes machining and this is where Swiss seriousness really shows itself. Computer controlled machines carve out the case with surgical precision. Holes for crowns pushers and case backs are cut. Curves are refined. Edges are sharpened or softened depending on the design. Dozens of measurements are checked constantly because even a microscopic error can compromise water resistance or comfort on the wrist. This is also where design identity starts to appear. A Carrera case feels different to an Aquaracer for a reason. Proportions thickness angles and lug shapes are all carefully engineered to match the personality of the watch.

Brushing

Now we reach the stage collectors obsess over finishing. This is where a case goes from technical object to design statement. And there is not just one way to do it. Brushing is often used on sports watches. It gives a clean purposeful look and hides scratches better than a mirror finish. The brushing itself must be perfectly aligned because uneven grain sticks out like a bad haircut.

Polishing

The opposite end of the spectrum. High gloss reflective and utterly unforgiving. One mistake and the entire surface has to be redone. Polished bevels are often combined with brushed surfaces to create contrast and visual drama. Then there is micro blasting or satin finishing which produces a soft matte surface. Tool like stealthy and very modern. Some cases even combine all three finishes brushing polishing and blasting in one design. This is not decoration for the sake of it. Each finish affects how light plays across the case and how the watch feels on the wrist.

Lacquer

Before final polishing many cases are coated with a temporary coloured lacquer. This acts like a highlighter pen showing exactly where material has been removed and where it has not. It sounds simple but it is brutally effective. Machines do the heavy work but the final judgement is always human. Skilled technicians inspect each case by eye and by touch because fingers can detect imperfections machines cannot.

Once finished the case is cleaned thoroughly because dust is the enemy. Crowns pushers gaskets and sapphire crystals are fitted. Casebacks are secured. Everything is tested for water resistance pressure and durability. Only then is the case ready to receive the movement it exists to protect. The funny thing is most people talk endlessly about movements and dials while ignoring the case entirely. Which is odd because the case is what takes the knocks resists water survives heat cold sweat and stupidity. It is engineering sculpture and armour all at once.