Flip over a luxury watch and there they are, sweeping across the movement like perfectly groomed lawn stripes at a stately home. Geneva stripes look dramatic, expensive, and faintly theatrical. And just like most wonderful things in watchmaking, they are completely unnecessary. The watch would run exactly the same without them. Which is precisely the point. Because Geneva stripes exist not to improve performance, but to prove that someone, somewhere, cared far more than they strictly needed to.

What Are Geneva Stripes, Really?

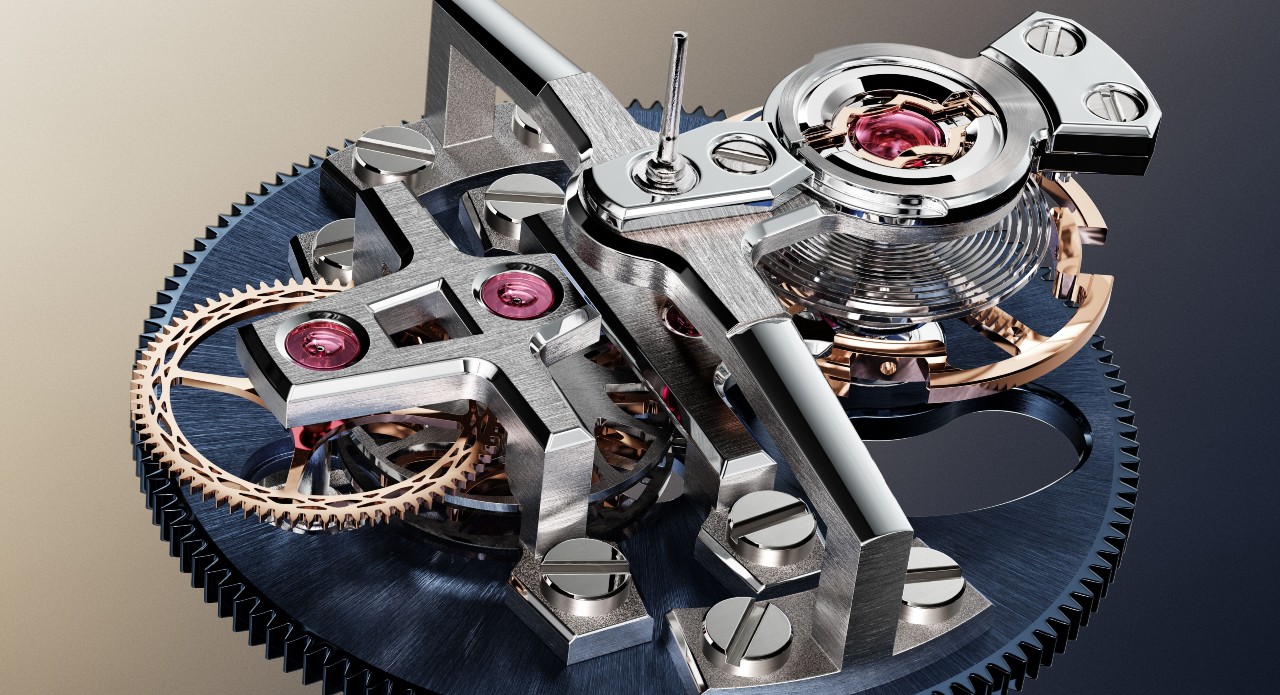

Geneva stripes, or Côtes de Genève if you want to sound serious at a dinner party, are decorative linear waves applied to the bridges and plates of a mechanical movement. They are not random. Each stripe must be parallel, evenly spaced, and consistent in texture. When light hits them, they shimmer and shift, giving the movement depth and motion even when the watch itself is standing still. In short, they make the movement look alive rather than like a lump of industrial metal.

Why They Matter Even Though They Do Nothing

Let us be clear. Geneva stripes will not make your watch more accurate. They will not improve power reserve. They will not save it from an unfortunate encounter with a marble floor. What they do is expose discipline. One uneven pass and the whole bridge is ruined. One moment of impatience and the pattern looks messy forever. Geneva stripes are visual proof that the watchmaker can repeat the same action, with the same pressure, at the same spacing, again and again without messing it up. That sort of restraint tells you a lot about what else is happening inside the movement.

How Geneva Stripes Are Made

Traditionally, Geneva stripes are applied using a straight line engine or a rotating abrasive wheel. The movement component is fixed in place, and the abrasive tool is drawn across the surface in one smooth motion to create a single stripe. Then the part is shifted slightly and the process is repeated. Over and over. Get the spacing wrong and it shows. Apply uneven pressure and it shows. In high end watchmaking, this step is done after other finishing processes, so the stripes remain crisp and uninterrupted by screw holes, jewels, or edges.

Hand Applied Versus Machine Applied Stripes

Machines can do Geneva stripes very well these days. They are quick, neat, and efficient. But they are also a bit soulless. Hand applied stripes have subtle variations that catch light differently, giving them warmth and depth. They feel integrated rather than stamped on. When paired with polished bevels, black polished screws, and finely finished edges, hand applied Geneva stripes become part of a larger finishing conversation rather than a decorative trick.

Once upon a time, Geneva stripes had a practical role, helping trap dust in pocket watches. Today, they are symbolic. They tell you the brand values tradition, restraint, and finishing for its own sake. A movement with beautifully executed Geneva stripes is saying something very simple and very expensive. We did this because we could not bring ourselves to do it any other way. And in luxury watchmaking, that quiet obsession is what separates the good from the truly great.