In the world of horology, innovation often hides in the smallest components. The micro rotor is one such masterpiece — a tiny, efficient mechanism that forever changed the design and performance of automatic watches. While most watch enthusiasts know the broad concept of an automatic movement, few appreciate the ingenuity behind the micro rotor — a solution that blends functionality, engineering elegance, and aesthetic refinement.

The Function of a Micro Rotor

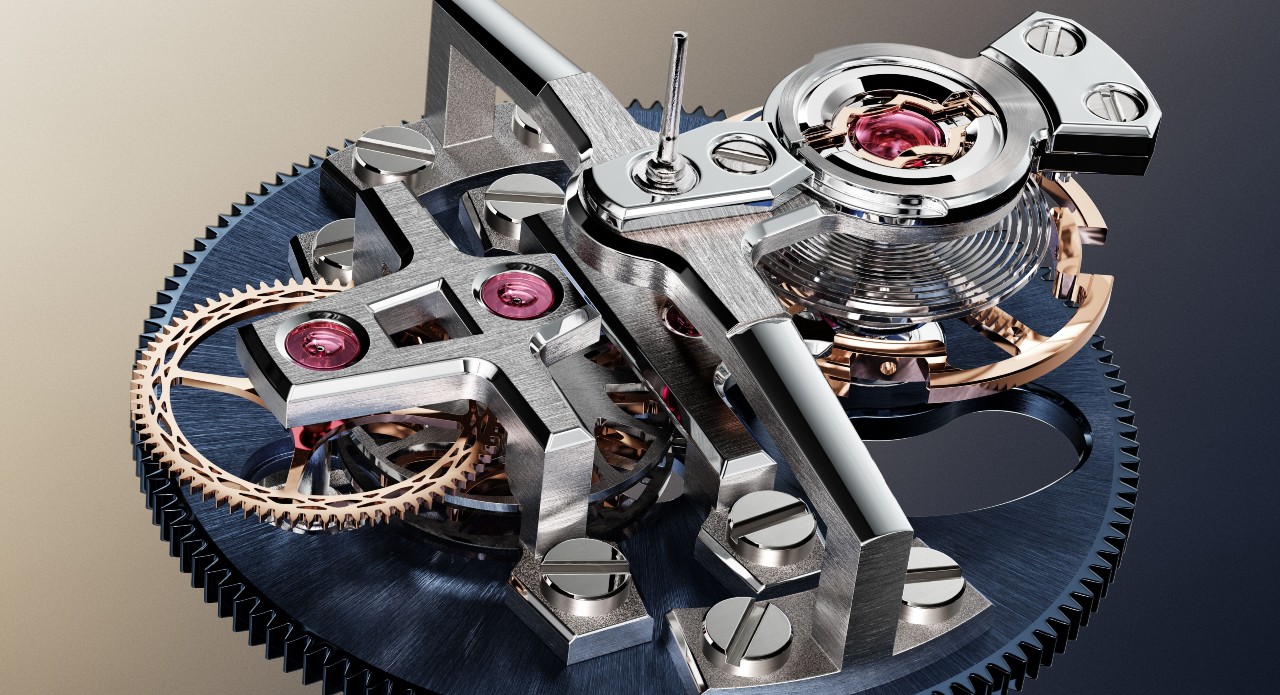

At its core, a micro rotor serves the same purpose as any other automatic winding mechanism: it converts the natural motion of the wearer’s wrist into energy to power the watch. However, unlike a traditional central rotor, which sits atop the movement and obscures much of the mechanical view, a micro rotor is cleverly integrated into the movement’s main plate itself.

This integration allows for a thinner profile, giving watchmakers the freedom to design ultra-slim automatic watches without sacrificing performance. The micro rotor spins bidirectionally or unidirectionally — depending on the design — to wind the mainspring through a series of gears. Despite its smaller size, when engineered with precision and the right materials (often 18k gold or tungsten for optimal mass), it can match the winding efficiency of its larger counterparts.

In essence, the micro rotor represents compact efficiency — doing more with less, without compromising the soul of mechanical watchmaking.

Who Invented the Micro Rotor and When

The story of the micro rotor dates back to the 1950s, a decade marked by a race for thinner, more refined automatic watches. The first brand to successfully commercialise the concept was the Buren Watch Company, which introduced its groundbreaking Calibre 1000 “Intra-Matic” movement in 1954. Buren’s innovation integrated the rotor into the movement rather than placing it above, allowing the entire calibre to be remarkably slim for its time.

This pioneering design was later licensed and refined by other major brands. Universal Genève, for example, embraced the concept with its Microtor Calibre 215, while Piaget elevated the micro rotor to haute horlogerie status with the ultra-thin Calibre 12P in 1960. These movements not only demonstrated mechanical excellence but also shaped the aesthetic identity of mid-century Swiss watch design.

Central Rotor

The most traditional and widely used design, the central rotor is a half-disc that sits atop the movement, rotating freely around a central axis. It offers strong winding efficiency and durability but adds height to the movement, making it less suitable for ultra-thin watches. This is the architecture found in most modern automatics, from Rolex’s Perpetual movements to ETA calibres.

Micro Rotor

In contrast, the micro rotor is integrated within the movement rather than above it. Its compact size allows for thinner cases, greater design flexibility, and a clearer view of the movement’s components. While earlier iterations sometimes struggled with winding power due to their smaller mass, modern materials and advanced bearings have largely overcome this limitation. The micro rotor remains a hallmark of high-end craftsmanship, appearing in brands like Patek Philippe, Chopard, and Laurent Ferrier.

Peripheral Rotor

A more recent innovation, the peripheral rotor takes minimalism a step further. Instead of being central or embedded, the rotor is mounted along the outer edge of the movement, encircling it entirely. This allows for an unobstructed view of the movement — perfect for open caseback designs — while retaining excellent winding efficiency. Brands like Carl F. Bucherer and Bulgari have championed this layout, pushing the boundaries of modern horology.

The Modern Revival of the Micro Rotor

After a period of relative obscurity in the quartz-dominated late 20th century, the micro rotor has seen a dramatic revival. Independent watchmakers and haute horlogerie houses alike have rediscovered its charm